As a high-end technological material, carbon fiber began to gain global popularity in 2010 and has occupied a mainstream position in the cycling industry since 2020. Carbon fiber is a high-performance fiber material composed mainly of carbon. It itself only acts as a “skeleton,” while the epoxy resin is what actually binds it together. The reason carbon fiber rims have become mainstream in road bikes, MTB carbon wheels, gravel bikes, and competitive cycling is that they offer significant advantages in weight, performance, stiffness, aerodynamics, and comfort.

1)Lightweight: Carbon fiber is extremely light while maintaining high strength, making it an ideal material for lightweight carbon rims. Lighter rims help reduce rotational inertia, which improves acceleration, climbing performance, and overall bike handling.

2)High strength-to-weight ratio: Carbon fiber has a strength-to-weight ratio far higher than traditional materials such as aluminum or steel. This allows carbon fiber rims to withstand high loads and impacts while keeping weight to a minimum, which is perfect for high-performance bike wheels.

3)Stiffness: Carbon fiber rims inherently have high stiffness, providing excellent power transfer and responsiveness. This stiffness translates into better handling, cornering performance, and overall ride feel, which is especially important in competitive road and MTB cycling.

4)Shock absorption: Carbon fiber has natural vibration-damping properties, helping to absorb road shocks and make rides smoother, particularly on gravel or off-road terrain. This is especially important because such conditions can increase rider fatigue.

5)Durability: Carbon fiber has a layered structure, a high fatigue limit, and is not prone to “softening.” Carbon fiber rims that are carefully designed can withstand impacts and wear. Advanced manufacturing processes and resin systems further enhance rim strength and lifespan, ensuring reliable performance over long-term use.

6)Corrosion resistance: Unlike metal rims, carbon fiber rims are suitable for winter riding, coastal areas, or wet conditions. Even in harsh environments, they are unlikely to corrode, rust, or oxidize. This corrosion resistance extends rim life and reduces maintenance requirements.

7)Aerodynamics: Carbon fiber can be molded into any aerodynamic rims design. Its surface is smoother, and edges transition naturally, reducing turbulence. For road bikes and time trial bikes, saving even 5% in wind resistance can potentially increase average speed by 1–2%.

8)Customization and branding: Carbon fiber rims can be customized by adjusting fiber angles, ply counts, and fiber modulus to achieve different performance characteristics. There are many options for patterns, logos, and branding, allowing unique designs and surface treatments to make products stand out and attract consumers.

9)Perfect match with disc brake systems: Carbon disc brake compatible rims almost eliminate heat fade issues. They also provide a cleaner appearance and easier maintenance.

It is precisely these advantages that make carbon fiber the ideal material for rim manufacturing, and especially for cyclists seeking high-performance equipment, high-performance bike wheels, or lightweight carbon rims to enhance their riding experience and competitive edge.

To achieve ultra-light rims and wheels, we invest significant time and effort in material selection. Fortunately, we ultimately finalized a high-toughness epoxy resin system to ensure strong bonding and impact resistance between carbon fiber and resin. After combining with epoxy resin, carbon fiber becomes prepreg material. This material is cut at different angles, stacked, and heat-cured to create solid carbon rims. Because stacking methods differ, the resulting rims have different versions and weights.

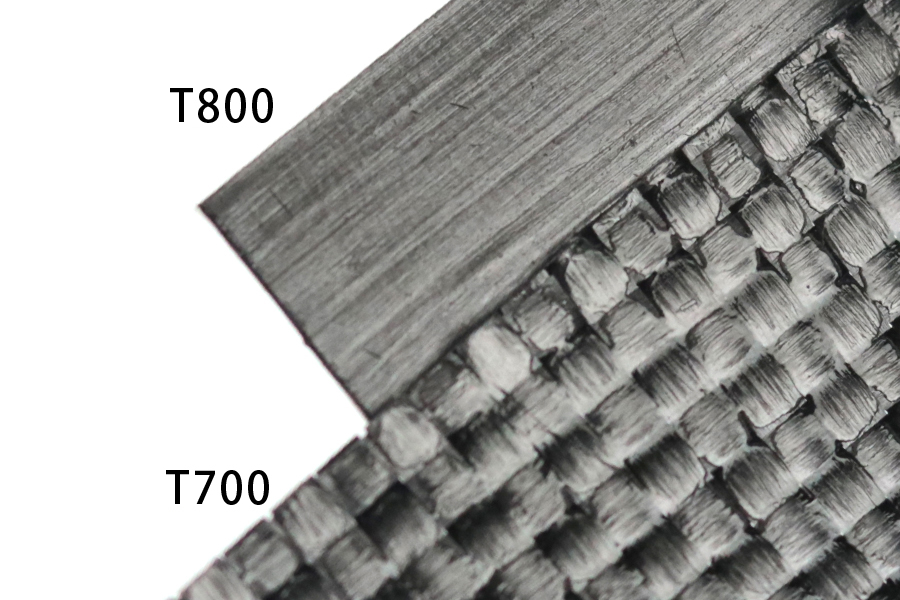

Currently, EIE mainly uses T700 and T800 materials, and small amounts of T1000 or T1100 are added in some stacking designs to achieve ultra-light target weights. T700 is mainly used in SD versions as well as XC, AM, DH, and Enduro stacking designs, making it ideal for riders who prioritize durability and smooth riding experience. T800 is used in stacking designs aimed at lightweight performance, achieving lower weight without reducing performance, providing more direct power transfer and faster responsiveness, which is perfect for competitive riders. T1000 and T1100 are used in small amounts in UL and ULL stacking designs, reducing rim weight further while maintaining high strength to achieve true ultra-lightweight carbon fiber wheels.

However, due to the very high stiffness of T1000 and T1100, rims made with these materials can feel relatively hard. Therefore, we do not recommend these for riders seeking comfort. On the other hand, for riders who demand high stiffness, have a lighter body weight, and ride on smoother roads, UL and ULL versions are suitable.

Each EIE rim version and corresponding weight is determined by our team through repeated testing and experiments, ensuring rim strength and performance while also considering rider safety and comfort. This is why, compared with competitors, our rims are lighter, stronger, and more stable in quality.

We can also customize the number of plies to reach your target weight. If you want to customize your rim weight, a minimum order quantity is required. Although we can customize stacking structures, we generally do not recommend this because it requires more time for redesign and testing, which may indefinitely delay your order.

If you have any questions about versions or if your riding conditions are special, please leave a message below or contact us directly, providing your specific requirements and intended use. We will provide professional recommendations for you.