Drilling is one of the most critical steps in carbon fiber rim manufacturing, as it directly affects the strength, weight, durability, and spoke tension balance of the wheelset. At EIE Carbon, all drilling is performed through CNC machining technology, ensuring high precision and consistency.Our rims feature angled drilling holes that are customized based on the hub flange width and angle. By tilting the holes toward the hub flange, spoke tension is more evenly distributed, minimizing lateral runout and improving long-term durability.

EIE Carbon rims include three types of holes: spoke holes, valve holes, and drain holes. Understanding their functions can help you decide whether to request custom CNC drilling for your next wheel build.

1.Spoke holes

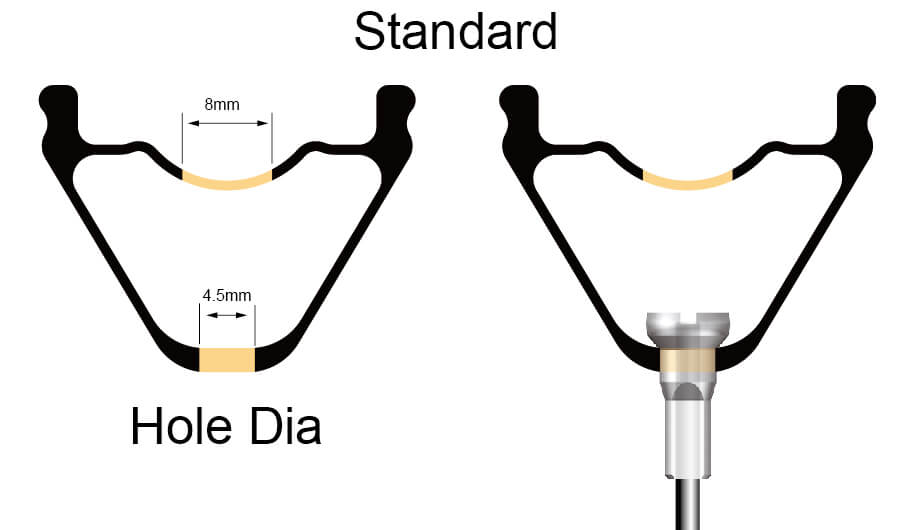

Spoke holes are located along the rim’s inner wall, allowing the spokes to connect the rim and hub. They determine the spoke lacing pattern and influence overall wheel strength. EIE Carbon offers three spoke-hole designs: standard holes, internal nipple holes, and without rim bead holes.

1) Standard holes (External holes) have a 4.5mm spoke-hole diameter and an 8.5mm rim bead hole. For carbon spokes, the rim bead hole diameter is 9.0mm. If your wheel build uses carbon spokes, please inform us in advance—our CNC drilling machine will adjust the size precisely to 9.0mm for tool compatibility. This is our default drilling style and the easiest for wheel assembly. However, for tubeless setups, you’ll need to apply tubeless rim tape for air sealing.

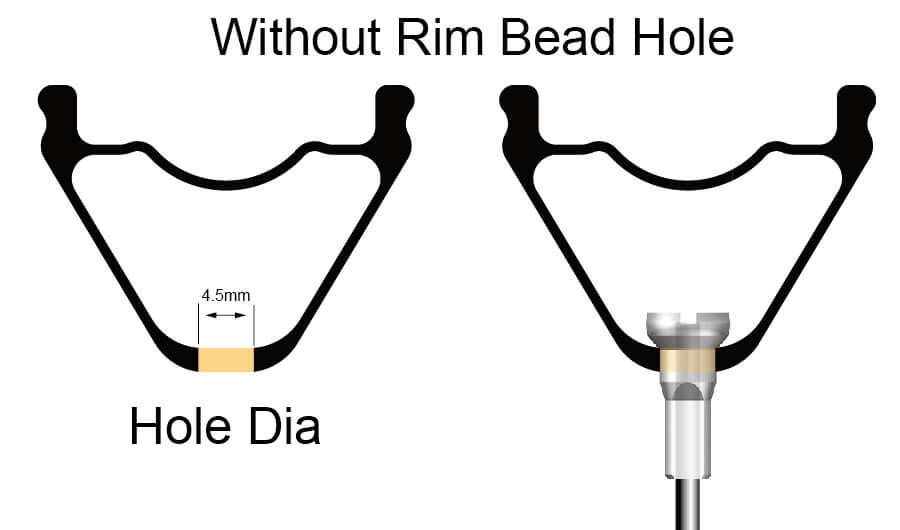

2) Without rim bead holes feature a completely sealed surface on the rim bed, with only 4.5mm internal spoke holes. This true tubeless-ready rim design eliminates the need for rim tape, improves sealing performance, and simplifies tire installation. It also avoids common sealing failures caused by poor-quality tape. However, for rims shallower than 22mm, we don’t recommend this option due to limited availability of compatible nipples and wheel-building tools.

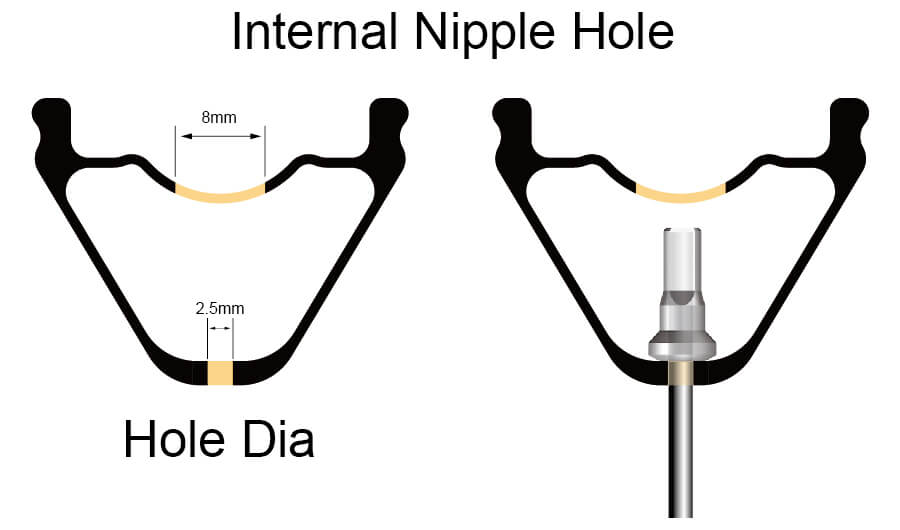

3) Internal nipple holes (Hidden holes) have a 2.5mm spoke-hole opening and a 9.0mm rim bead hole. Because CNC machining removes less carbon fiber material, these holes reduce the risk of cracking and increase overall spoke strength. They also deliver a cleaner, more aerodynamic appearance, as only the spoke heads remain visible.

Our default drilling type is 4.5mm spoke holes and 8.5mm rim bead holes.

If you prefer hidden or without rim bead holes designs, please specify your choice when ordering. All drilling angles and spoke-hole patterns are fully customizable through CNC precision machining—contact us for custom drilling requests.

Our default/standard hole type is external hole.

If you need hidden hole or no rim bead holes options ,please select the options you needed.

All spoke type can be customized .Please contact us if you need any special orders.

2.Valve Holes

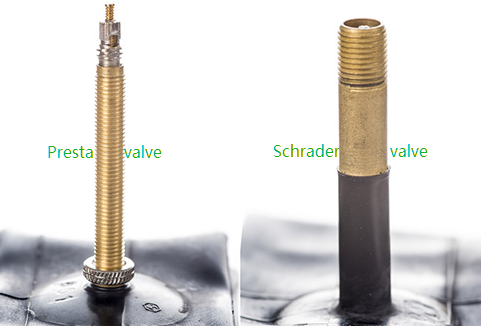

Two valve types are commonly used in bicycle wheels: Presta and Schrader.

EIE Carbon rims come with Presta valve holes by default, drilled to 6.5mm diameter—ideal for road, MTB, and fat bike rims. Presta valves are also recommended for tubeless-ready rims due to their superior air sealing and lightweight design.

We can also produce Schrader valve holes (8.0mm), commonly used in BMX and urban bikes.

If you have specific valve requirements, please contact us.The valve-hole diameters can be customized according to your needs.

3.Drain Holes

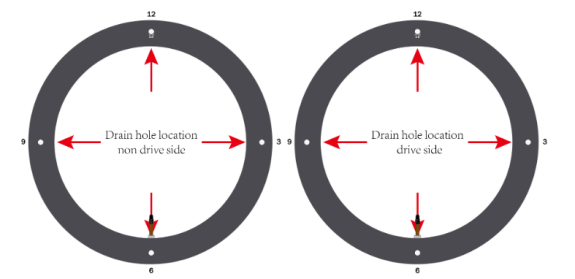

Drainage holes help remove moisture trapped inside the rim cavity during wet rides by using centrifugal force while the wheel spins.They are not included by default, but you can choose to add them—either one on each side or one single hole.

Typically, the valve hole is positioned at 6 o’clock, while the drainage hole is drilled at the 9 o’clock position on the non-drive side, with a 2.5mm diameter.

Custom positions or quantities can be specified during production.

If you’d like to customize drilling patterns, adjust spoke-hole angles, or optimize your rim for specific hubs, feel free to contact EIE Carbon.Our CNC machining process ensures accuracy, strength, and aesthetics in every carbon rim we produce.