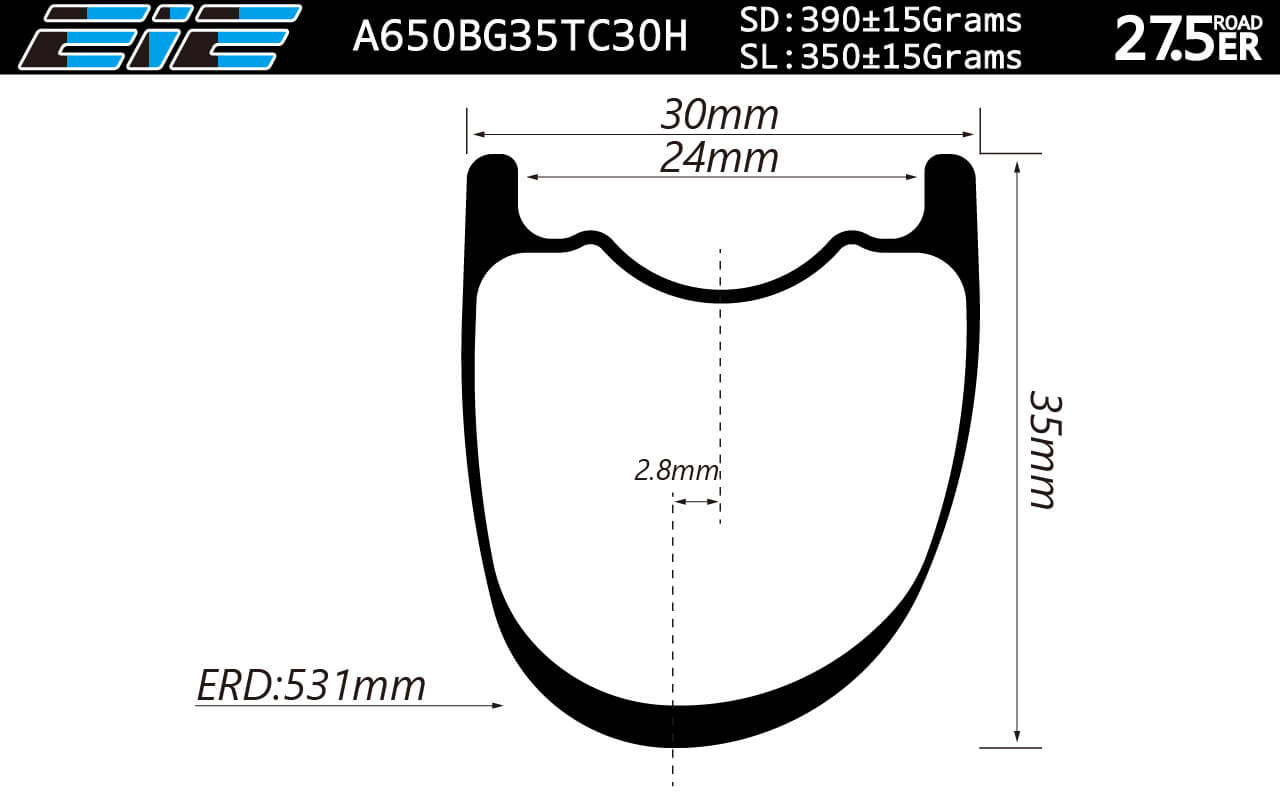

A650BG35TC30H ROAD CARBON RIMS AND WHEELS

650B 30mm wide 35mm deep tubeless for disc cyclocross and gravel bikes

- SPECS

- TECH

- WARRANTY

-

ProductItem: A650BG35TC30H Warranty: 2 YearsBasicSize: 650B Material: Toray (SD:T700 | SL:T700+T800) Rim Type: Clincher W/Hookless ERD: 531mm Outer Width: 30mm Inner Width: 24mm Depth: 35mm Offset: 2.8mm Spoke Hole Angle: ±8° Spoke Hole Dia: 4.5mm Valve Hole Dia: 6.5mm Assembly Hole Dia: 7.5mm Weight: SD:390±15G | SL:350±15GCustomizationWeave: UD/3K/3K Twill/12K/12K Twill/others Finih: Matte/Glossy/Satin/Colored/Others Hole Count: 12H~36HRecommendationWeight Limit: ≤130kg Tire Size: 28C-50C Spoke Tension: 120~130kgf front disc side and rear drive side Tyre Pressure: ≤75psi/ 5.17barApplicationSD: CX | Gravel SL: CX | GravelNote1: SD(Standard/Common) version is constructed by fully carbon fiber T700 . 2: SL(Superlight) version is cnstructed by blend of carbon fiber T700+T800.HUBSModel: DT SWISS 180, DT SWISS 240 EXP, DT SWISS 350, Chris King R45D, Novatec D411SB / D412SB, Carbon-Ti X-Hub, ARC MT-032, Bitex BX312F / BX312R Front Axle Size: 12*100mm,15*100mm,QR*100mm Rear Axle Size: 12 / 142mm, QR / 135mm,QR*130mm Driver Body: Shimano Road 11S,Sram XDR, Campy 11S Hole: 20H,24H,28HOTHER PARTSSpokes: Sapim CX-Ray,Sapim Race,Sapim D-Ligh,sapim CX Sprint,Pillar Aero X-TRA 1420,EIE Carbon Spoke ECS,Pillar 1423,Sapim Leader Nipples: Aluminium Black, Aluminium Red, Brass Black, Aluminium Blue, Aluminium Gold, Aluminium Green, Aluminium Orange, Aluminium Purple

-

All of our EIE road rims share with the following manufacturing technologies:

1.Super light WeightT700The SD version were fully constructed Premium Toray T700 Carbon fiber.T700+T800 component:The SL series EIE carbon rim were constructed with properly component of Toray T700+T800.We cut the material size of the nipple bead area and strengthen the key parts of spokes to maintain the strength of the overall carbon rims.2.Layer-upThe layer-up of each carbon rim is carefully designed, repeated tests and then determine final standards document.

After that,we’ll send it to our layer up workers, who operate according to the operating standards.They cut the size of the material according to the layer- up instructions to produce materials for any part that can be used to increase the strength of the side part of the wheel set, to fit the grooves of the rims, to enhance the impact resistance of the wheels.All EIE's carbon rims were manufactured by a one-piece continuous layer.This uninterrupted layer not only produces a stronger rim, but a lighter one!3.Angled Hole Drilled By CNC MachineThe spoke hole angle design of the rim is very important , but its design angle range is limited .If the design does not match the design of the spoke hole angle of the hub , the bending phenomenon of the spoke can be generated .When our EIE carbon rims drill angled holes, the spacing and angle of each hole are calculated accurately to ensure that when the rim is connected to the drum through the stripes, no additional pressure is generated around the rim hole.We use a high speed CNC machine to drill all the holes to avoid spoke holes area carbon fiber strength reduction ,thus making the wheels build stronger.4.Smooth Rim Inside SurfaceThe air bladders are made from a special material which has ability to produce very smoother walls, result in a lighter rim, and are completely removed without harsh chemicals.They are removed through the valve hole with a unique process by a skillful workers .So you would not see any patched hole on rim bed,that produces a stronger rim.5.High TG Rim Brake TrackAll of EIE non disc brake surface were used for high TG resin system that to prevent the overheating while biking at high speed.It is combined with the grid 3K brake track ,that allows to withstand temperatures in excess of 280 degrees Celsius ,then dissipates heat ,and cooler rim temperatures quickly.6.Grooved Graphene Brake TrackOur graphene version of the high TG brake track has better overheat resistance, improved heat dissipation, and reduced temperature accumulation during severe braking.The grooved brake tracks help to disperse the moisture between the pad and the brakes in wet conditions and bring more better braking resistance in dry conditions7.Tubeless Compatible Technology(Tubular Except)All of EIE tubess compatible rims are designed with bead seat on rim bed and a tire pump is needed to seal our rims while assembly .We from the actual use to consider the bead shape, bead seat and outer diameter to make sure the best fit with each rim.Even though tubeless (no tube is required) systems are required at lower pressures than tube systems,but without any negative effects.It improves better on lower rolling resistance, decreased rotational weight and flat resistance . -

EIE Carbon offer this warranty is aimed to ensure that all products we sell are free from defects and all passed the QC test before shipment.EIE Carbon carries 2-year warranty (from the date of purchasing) for all carbon bike rim we sell including the existing MTB rims ,road rims,fat bike rims,BMX rims and upcoming new models.EIE Carbon Offer Warranty For Rims1.Within 6 months from date of purchase:If the rim quality issue is caused by manufacturing defects. EIE Carbon will send you the free replacement rim and bear the re-sending freight,but other expenses shall be adsorbed by the buyer.2.After 6 months from date of purchase:Free replace the damaged rims. EIE Carbon and customers shall bear 50% of the freight cost respectively.EIE Carbon Offer Warranty For Wheels1.Within 6 months from the date of purchase1)UsedIf the wheels quality is caused by rim manufacturing defects.EIE Carbon will send you the free replacement rim,bear the reshipment’s freight and compensate $30 for customers to rebuild wheels in local bike shop,but other expenses shall be adsorbed by the buyer.2)UnusedIf the wheels quality is caused by rim manufacturing defects.Customer is not allowed to use the wheels and EIE has right to ask buyer to send the whole wheels back to us.We will rearrange to send new wheels to customer after receiving the returned package within 2 weeks .In this case ,EIE will bear the shipping cost for returned package $50 at best as well as the shipping cost for resent package.The shipping cost of returned package will be refunded to customer by PayPal.The other expenses shall be adsorbed by the buyer.If the wheels quality is caused by rim manufacturing defects and EIE does not need customer to send it back to us.EIE will send new free replacement rim to customer,bear the reshipment's freight and compensate $30 for customers to rebuild wheels at local bike shop,but other expenses shall be adsorbed by the buyer.Extra problems like accessories please contact customer service for assistance2.After 6 months after the date of purchase:If the wheels quality is caused by rim manufacturing defects.EIE Carbon will send you the free replacement rim as well as bear the reshipment's freight .But other expenses shall be adsorbed by the buyer.More at WARRANTY page.